Podcast: Play in new window | Download

Subscribe: Apple Podcasts | RSS | More

Building any type of infrastructure is challenging, whether it be a house or a skyscraper. The difficulty is only compounded when you are building in the remote desert, a coastal town recently hit by a hurricane, or even an observatory on a high mountain. In some locations, it is difficult and downright expensive to bring in building materials.

What if, instead, you could use a 3D printer and print a building, using the dirt and soil that’s already found at your build site? Then, you wouldn’t have to lug costly building materials for miles. 3D printed buildings may not be that far off. In fact, today we’re talking to Keegan Kirkpatrick, the founder and CEO of RedWorks Construction Technologies Inc. RedWorks is a startup seeking ways to produce construction material, and eventually an entire building, using a 3D printer. This would this dramatically reduce building costs. All sorts of architectural styles could be imagined. And buildings could go up even in the most remote of locations.

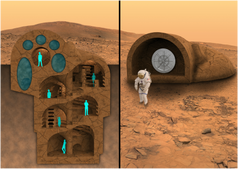

And what’s more remote than Mars? It’s possible to use this same technology to construct 3D printed buildings on the Red Planet, allowing astronauts and first colonists to not have to rely on resupply missions for materials, making life there more feasible.

This image is of a concept of a 3D printed house on Mars. It has a honeycomb structure, and is made of entirely Martian dust.

You can follow RedWorks at @RedWorksCTI.